Distribution companies certainly provide quality and complete services so they need a system that is in line to provide significant changes. One of them is by using a Warehouse Management System (WMS), which is a system created with the aim of facilitating the performance of warehouse management in an end-to-end process (a process that uses a system or service from start to finish, which provides a complete functional, without the need to use a third party).

Warehouse Management System has several benefits for companies, including, increasing flexibility and responsiveness, storage time and picking goods become more efficient. Increased warehouse inventory accuracy so that it can reduce warehouse operational costs and be more efficient during the stock-taking process and reduce the occurrence of dead stock. In addition, it also makes it easier to supervise. Effective warehouse management is very important to maintain smooth operations and customer satisfaction.

Medion Ardhika Bhakti has applied the Warehouse Management System to provide efficiency and transparency needed in the process of distributing products to customers with the following applications:

- – Apply FIFO (First In, First Out) and FEFO (First Expired, First Out) rules

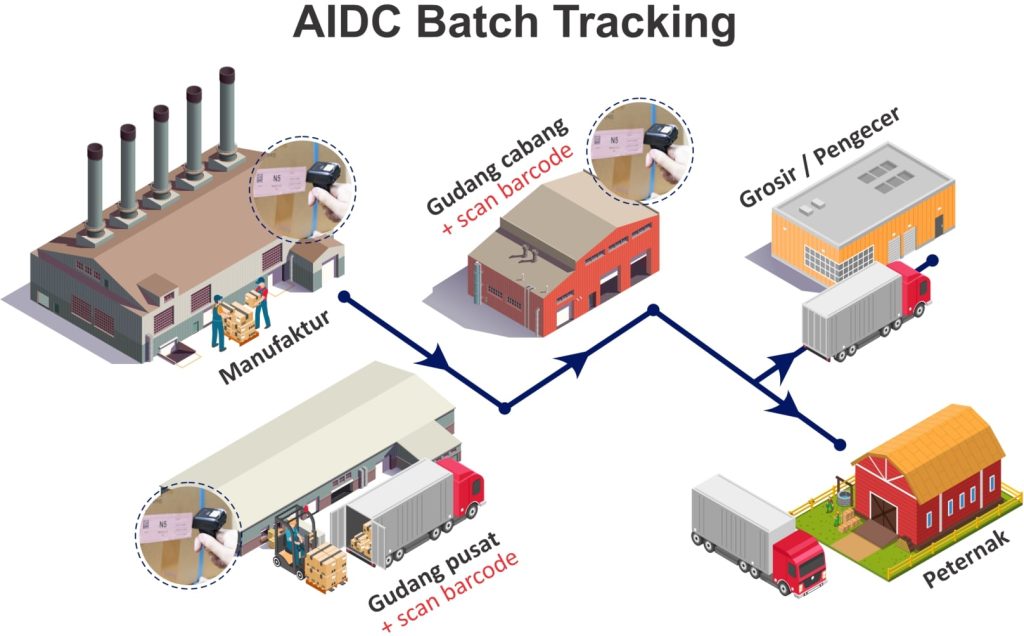

- – Implement a batch tracking system supported by Automatic Identification and Data Capture (AIDC) technology

- – Has an ERP (Enterprise Resource Planning) program in the form of Epicor, Medical and Modist applications

- – Have adequate warehousing and distribution infrastructure in accordance with product requirements

With the use of this system, of course, marketing activities and distribution of Medion customer needs throughout Indonesia can be fulfilled quickly and precisely. This is in line with Medion Ardhika Bhakti’s commitment to become a trusted main partner in distributing and marketing quality products throughout Indonesia.