Medion has been serving the livestock industry for over 45 years and continues to prove that its quality follows international standards. Having previously been certified ISO 9001:2008 regarding Quality Management Systems and updated with the latest standard, namely ISO 9001:2015, Medion continues to take opportunities for improvement in its services.

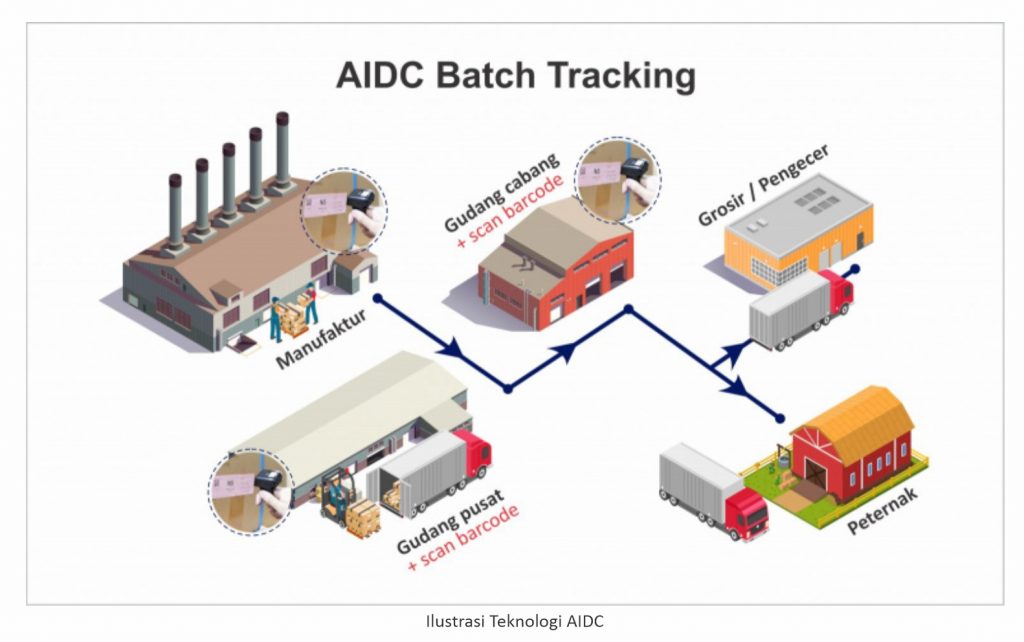

In addition to having implemented Cold Chain Management or Cold Chain Management as an effort to ensure that the distributed vaccines maintain their quality, Medion also continues to follow technological developments related to manufacturing and distribution. Medion ensures that the system used is able to track and trace products on the market quickly and accurately. This is done by changing the manual process to automatic with AIDC technology (Automatic Identification & Data Capture). AIDC technology enables fast, easy and accurate identification of product data and history. Why is this important?

Before continuing to further discussion, it is a good idea to know the terms used in production and distribution activities. Batch Production is a number of vaccines produced at the same time and using the same ingredients so that they have the same quality and expiration date. Number batch, which consists of numbers and/or letters, will be the identifier for vaccines produced in one batch. Number batch are unique and recorded or noted so as to enable tracking or tracing back the complete history of vaccine manufacture, end-to-end, starting from the production, supervision and distribution stages. The tracking or tracing process is based on the number batch disebut batch tracking. This is in accordance with the Decree of the Minister of Agriculture No. 466/1999 concerning Guidelines for Good Animal Drug Manufacturing Practices (CPOHB). Not only domestically, this system has also been implemented for export vaccines.

Recording or noting numbers batch must be done well so that batch tracking can be done effectively and efficiently. Currently, Medion does it with AIDC technology (barcode symbology 2D Data matrix), automatic vaccine identification method, collecting data about vaccines and storing them in a computerized system. There are many benefits to be gained by implementing AIDC technology.

First, better warehousing activities. FEFO system (first expired first out) can be controlled well. In addition, it can minimize the potential for errors because human-error in the process of preparing vaccines to be sent to branch offices and to farmers. Second, efficient product tracking and tracing. With AIDC technology, vaccine tracking can be done quickly, easily and accurately. This will be very beneficial for farmers and producers because farmers can find out information on product authenticity, manufacturing date, expiration date or where the product comes from. In addition, it is also useful for tracking purposes related to product questions and complaints.

Third, increasing audit quality. With an integrated tracking and tracing system, the government and Medion can jointly control manufacturing documentation. The movement of products from production to distribution to the hands of farmers can be described clearly and completely. This is certainly not the end to remain the trust of farmers, Medion will continue to innovate and follow developments.