A heating device is absolute thing that need to be provided during the brooding period. There are several heating alternatives that can be used in closed house. Each type of heater has its advantages and disadvantages. Thus the breeders need to choose the right type of heater so cost efficiency and optimal livestock performance can be achieved.

Heater Needs

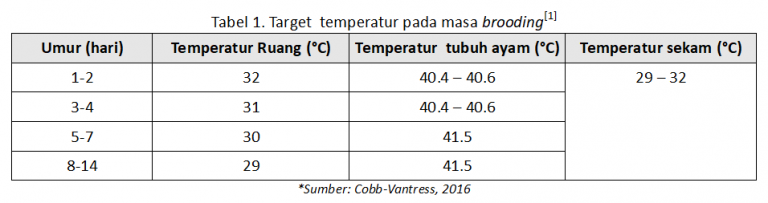

Chick which age is up to 2 weeks (during the brooding period) have not been able to regulate their body temperature properly, so a heater is needed to warm the chick’s body. During the brooding period, three parts of the temperature must be considered, whic is the room, the chicken body, and the husks.

Recording Cage Temperature Regularly

Recording the cage temperature regularly in the morning, afternoon, evening and night, including seeing the response of the chicken, is there anything important or not. In the cage, there are at least 3 points to measure the cage room temperature using a thermometer: in front of the brooding area, in the middle, and in the back of the brooding area[2]. Position the thermometer as high as the chicken (40 – 60 cm from the husk) when checking the cage air temperature [2].

Other than that, it is necessary to ensure the warmth of the husks. The cage air will warm faster than the husks. Simply measuring the cage air temperature does not guarantee that the husk temperature is right [3]. Use an infrared thermometer for accurate measurement of the husk temperature. Practically, the breeder can kneel to feel the husk temperature with the palms [3].

Alternative Heater

In general, the heater that used in closed house is a type of heater fueled by LPG gas. This is because the gas heater is easy to operate, does not produce smoke pollution (does not interfere with the health of the chicken), and LPG gas fuel is easy to obtain[4]. There are 2 types of gas heaters that are commonly used in closed house cages [5]:

- Spot heater

- Space heater

Spot Heater

Spot heater is a tool that focuses heat at one specific point / one area only. Spot heater can be infrared heater and non infrared heater.

Infrared is an energy which carries heat and its easily absorbed by the chick[4]. Infrared is generated in large amount by infrared heaters such as IGM.

The air will enter through the IGM Air Filter and mix with the LPG gas in the IGM Gas Heating Body and there is a combustion fire. The fire will hit a special ceramic[6] on IGM so almost all of the fire energy is converted into infrared energy (heat). Infrared is heat that can easily absorbed by chicks.

Infrared Heater Advantages

Infrared heater (such as IGM) have several advantages compared to non-infrared heater (such as Semawar) as shown in Table 2.

Spot Heater’s Location

For the circular brooding area with a capacity of 1000 chickens, you can use the IGM spot heater which is placed on 1/3 of the brooding side with a minimum height is 1 meter from the husk. Position the slope of the IGM to 15o so the heat’s distribution from the IGM is more optimal.

For the square brooding area, it can be done in the middle of the cage with the position of spot heater as shown in Picture 6. The number of spot heaters is adjusted to the tool’s capacity and the broiler’s population.

Space Heater

Space heater is a heating device that heats all the air in the cage[5]. One type of space heater is Central Heater or Super Saver Heater. Central Heater is a space heater fueled by LPG gas and equipped with a fan to circulate warm air. Central heater requires 250 – 430 Watt, 230 Volt, 1 electricity phase power source[8]. In addition, the central heater is also equipped with a safety device to prevent cage fires. Every purchase of a central heater includes:

- 1 unit of central heater

- 1 unit of holder frame

- 1 unit of black gas hose

And every purchase of a central heater DOES NOT include:

- Electrical connector head (connector to power source)

- Gas regulator as connector to LPG cylinders

Central Heater Main Components

The main components of the central heater are on the side, back side and front side, and the inside of the central heater machine. The side of the central heater has a door that can be opened and closed.

A. Side of the central heater

Some of the main components and functions on the side of the central heater are:

B. Back side of the central heater

Some of the main components and functions on the back side of the central heater are:

C. Front side of the central heater

The only important component on the front side of the central heater is Flare duct. Flare duct is a channel that functions is as a place for hot air to escape and can regulate heat flow direction. Beside that, the important thing to do is adjust the sheet metal position inside the flare duct to determine heat flow direction [9].

D. Inner side of the central heater

There are some of the main components which is in the inside of the central heater. That components only can be seen if there are demolition central heater machine. The components and functions are:

Central Heater Work Mechanism

Air will enter the machine through the lattice at the rear of the machine. The air will contact with conductor material of the combustion chamber so it becomes hot. Then the hot air is pushed out by the blower through the flare duct towards the cage[9]. The central heater will heat up all the air in the cage until it reaches the desired temperature (after setting the thermostat).

The central heater will turn on and turn off automatically according to the room temperature which is detected by the sensor inside the central heater. The central heater will turn on if the temperature has not reached the target temperature setting. And the central heater will turn off if the room temperature has reached the target temperature setting value.

Central Heater’s Location

In general, central heater is placed at ¼ from the entrance or in front of the brooding area. There are 2 ways of placing the central heater, whic is in series or in parallel. The different ways of placing it can be seen in the appendix.

The minimum distance of the central heater to the base of the cage is 0.5 meters (use a holder frame). Keep the flammable materials away from the central heater. Husk, rations, or other materials should not be stacked on top of the machine. Place the central heater with a minimum distance of 3 meters from livestock[11].

Comparison between Space Heater & Spot Heater

Each type of heater has its advantages and disadvantages. The comparison between space heater and spot heater can be seen in table 3 :

References

[1] The Importance of Chick Start. Cobb-Vantress. 2016.

[2] Info Medion Edisi Juli 2010: Suhu dan Kelembaban Terkontrol, Ayam Nyaman.

[3] Broiler Signals. 2015. Netherlands. Roodbont Publishers. Marteen de Gussem.

[4] Info Medion Edisi Januari 2013: Agar Pemakaian Pemanas Gas Lebih Efisien.

[5] Modern Broiler House Heating Systems. 2017. Mississippi State University Extension

[6]Infrared (Radiant) Heating Basic Information. 2015. MOR Electric Heating Assoc., Inc.

[7] Standar Redaksi Brosur IGM 2016

[8] http://sinarmustikaraya.com/hh-super-saver-heater-hh-super-saver-heater/

[9]Pengamatan tim RDPE Medion terhadap Central Heater. Agustus 2017[10]Poultry House Heating System: The University of Georgia

[11] Owner’s Manual Super-Saver XL Heater. Hired Hand Manufacturing, Inc.